IBR FITTINGS

-By Arshya Pipe Fittings Pvt.Ltd.

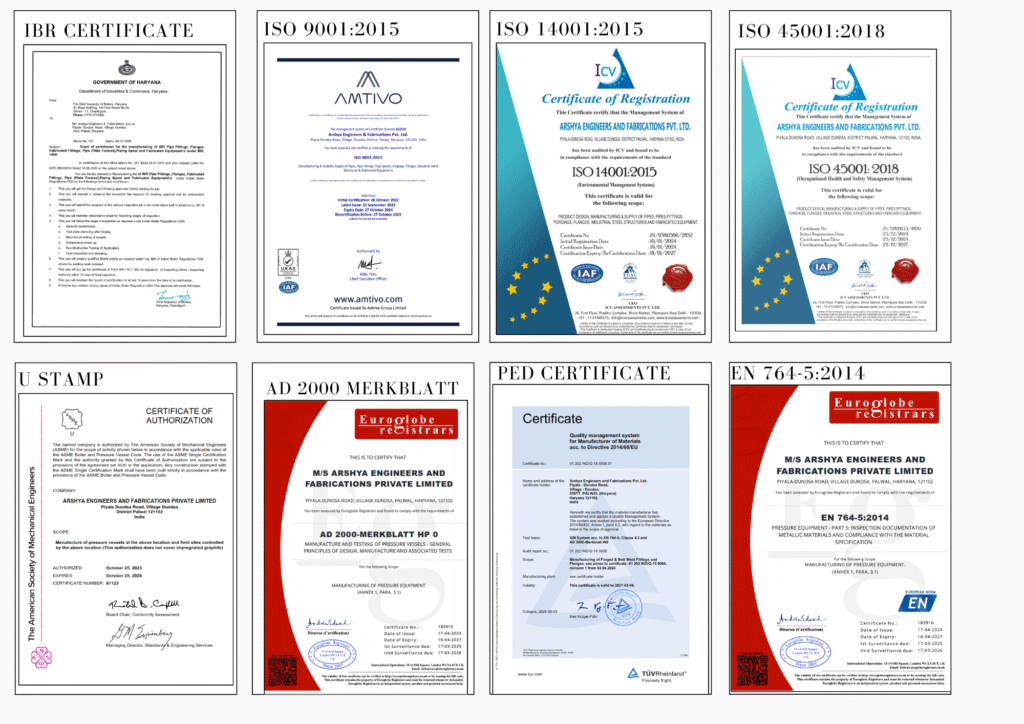

An IBR, ISO, PED, U Stamp, AD 2000 Approved Manufacturer.

CERTIFICATIONS AND ACCREDITATIONS

At Arshya, we are committed to delivering products and services of the highest quality. Our dedication to excellence is reflected in our comprehensive range of certifications and accreditations:

- Indian Boiler Regulations (IBR)

- ISO 9001:2015 – Quality Management Systems

- ISO 14001:2015 – Environmental Management Systems

- ISO 45001:2018 – Occupational Health and Safety Management Systems

- Arshya is accredited with the ‘U’ stamp by the American Society of Mechanical Engineers (ASME) for the manufacture of pressure vessels.

- We are also recognized under:

- EN 764-5:2014

- AD 2000-Merkblatt HP 0